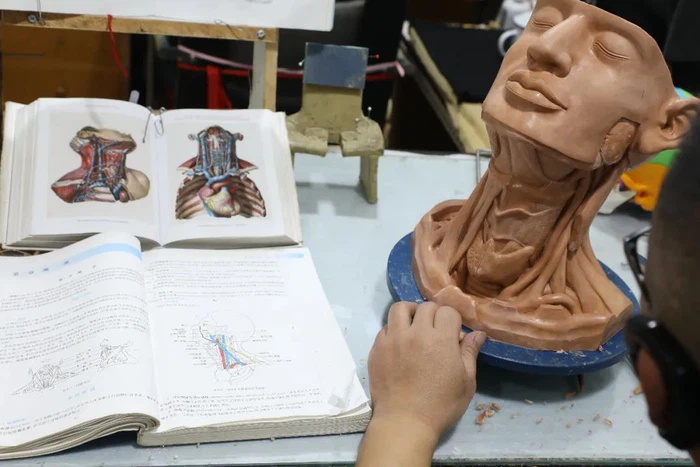

First, sculpture & shaping

Combined with the current domestic latest medical teaching materials and the latest atlas of international authorities, according to the needs of customers, or doctors and students to create more subtle and unique realistic products, molding artists use food grade fine sculpting oil clay sculpting. Environmental clay sculpting model details, lifelike.

Second, mold manufacturing

Deployment of environmental protection silicone, in the fine carved modeling, repeated silicone production, or covered with gauze to strengthen the mold, and finally plaster fixed mold molding.

.jpg)

Third, painting & rapid solidification

Adjust food-grade silicone gel according to the proportion, fill color painting in the corresponding mold parts according to the different colors of each organ on the produced mold, divide the layers, fill color layer by layer, maintain the corresponding thickness, and proceed to the next step after curing.

.jpg)

Fourth, fill with foaming agent

Pour an appropriate amount of foaming agent into the prototype mold of the product, and the product will be lighter and have texture, easy to teach and learn.

.jpg)

Fifth, compound die & edge sealing

After foaming, silicone rubber is poured into the product mold, and the product mold is fitted up and down, fixed with plaster, trimmed and beautified. The product production is completed, and the finished product is environmentally friendly, practical and beautiful.

.jpg)